A cable harness, which can be also known as a wire harness, cable assembly, wiring assembly, or wire loom, is a grouping of wires and/or cables that are used to transmit signals and to provide electrical power if needed. The wires and cables are joined together using straps, cable ties, cable lacing, tubing (either shrink tubing or non-shrink tubing), sleeving, electrical tape, conduit, braided extruded string, or any combination of these.

A cable harness is most commonly designed according to the geometric and electrical requirements of the ultimate piece of equipment it will be installed in. A simple harness could consist of as few as three discreet components but they more typically include dozens of different wires and possibly hundreds of components. The wires and cables used to construct a wire harness are usually hook-up wires, coaxes, multi-pair cables, and multi-conductor cables. A complex wire harness may include any combination of these various types of wires and cables, all dependent on the design of the harness.

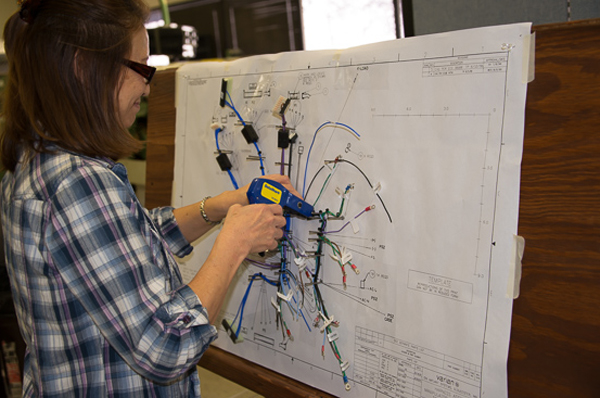

Once the design of the wire harness is determined, a full size diagram is usually provided for the assembly preparation and assembly. Based on this diagram, the wires are cut to desired lengths with the use of wire cutting machinery. During the cutting phase the wire ends may also be stripped of insulation in preparation for further manufacturing steps. The cut wires may also be printed at this stage for use identification in the overall harness, though in some instances the marking is completed during a separate operation. With the ends of the wires exposed because of the stripping operation, they can now be attached to any required terminals or connectors. Again the attachment of the terminals or connectors may be an automated process done on specialized equipment. The terminated wires and cables are routed, assembled, and clamped together on a specialized workbench known as a pin board or assembly board. This work bench is a full size layout of the wire harness and is built in accordance with the layout specifications detailed at the beginning phase of the wire harness design process. The harness is also fitted with any ties, protective sleeves, conduit, or lacing at this point and when the harness is completed it is tested and shipped for inclusion into the larger equipment it was designed for.

In contrast to the trend of increasing automation, wire harnesses continue to be mainly manufactured by hand, due to the variety of different processes involved. These processes include but are not limited to the following:

There are parts of the manufacture of a wire harness that can be automated however. Automation can be effective in:

Because of the lack of automation, wire harness production takes longer than other types of cable assemblies. The entire process can run from a few days to several weeks, depending on the complexity of the harness – the more complex the harness typically the longer the production time.

For additional information on cable assemblies visit our website and feel free to take a look at our cable assembly case study.

A cable harness is most commonly designed according to the geometric and electrical requirements of the ultimate piece of equipment it will be installed in. A simple harness could consist of as few as three discreet components but they more typically include dozens of different wires and possibly hundreds of components. The wires and cables used to construct a wire harness are usually hook-up wires, coaxes, multi-pair cables, and multi-conductor cables. A complex wire harness may include any combination of these various types of wires and cables, all dependent on the design of the harness.

Commonly Used in the Transportation Industry

The most common use of a harness is in the transportation industry, which would include automobiles, buses, trucks, planes, etc. Wire harnesses can also be found in construction machinery, industrial equipment, data communications related equipment, white goods, consumer products, or used inside box builds or any other electro-mechanical components. A wire harness will simplify the manufacture of any of these products by integrating all the wiring into a single combination that allows for a drop-in installation. For example, automobiles, buses, trucks, and planes have many components that require wires for them to perform. All of these wires add up to miles in length. A wire harness simplifies the installation of the wires by grouping the wires into a compact, simplified bundle that can be installed in one operation instead of running all of the individual wires – decreasing installation time. By joining the wires, terminations, and other components into a harness, the components can be secured much more effectively against the effects of vibrations, abrasions, and in some instances moisture. Using a wire harness will also optimize space inside of the larger component and decrease the risk of shorts during the initial install or during later field repairs. Incorporating the use of flame retardant sleeves into the harness also aids in lowering the risk of electrical fires inside of the larger piece of equipment. |

| Wire Harness Assembly in Largo, FL |

Once the design of the wire harness is determined, a full size diagram is usually provided for the assembly preparation and assembly. Based on this diagram, the wires are cut to desired lengths with the use of wire cutting machinery. During the cutting phase the wire ends may also be stripped of insulation in preparation for further manufacturing steps. The cut wires may also be printed at this stage for use identification in the overall harness, though in some instances the marking is completed during a separate operation. With the ends of the wires exposed because of the stripping operation, they can now be attached to any required terminals or connectors. Again the attachment of the terminals or connectors may be an automated process done on specialized equipment. The terminated wires and cables are routed, assembled, and clamped together on a specialized workbench known as a pin board or assembly board. This work bench is a full size layout of the wire harness and is built in accordance with the layout specifications detailed at the beginning phase of the wire harness design process. The harness is also fitted with any ties, protective sleeves, conduit, or lacing at this point and when the harness is completed it is tested and shipped for inclusion into the larger equipment it was designed for.

In contrast to the trend of increasing automation, wire harnesses continue to be mainly manufactured by hand, due to the variety of different processes involved. These processes include but are not limited to the following:

- Installing terminated wires in varying lengths

- Running wires and cables through sleeves and conduits

- Taping the harness with fabric tape at branch outs

- Conducting multiple crimps on specified wires (more than one wire into one terminal)

- Binding the various components with tape, clamps, or cable ties

There are parts of the manufacture of a wire harness that can be automated however. Automation can be effective in:

- Cutting and stripping the ends of individual wires by using specialized cutting machines

- Crimping terminals on one or both sides or the wires

- Plugging of wires previously fitted with terminals into connector housings

- Soldering or tinning of wire ends

Because of the lack of automation, wire harness production takes longer than other types of cable assemblies. The entire process can run from a few days to several weeks, depending on the complexity of the harness – the more complex the harness typically the longer the production time.

For additional information on cable assemblies visit our website and feel free to take a look at our cable assembly case study.